three. All of these checks must be Evidently documented during the respective log book together with during the reference validation protocol & Report

sixty seven) point out certain kinds of cleaning validation. Even so, it is generally recognized during the pharmaceutical sector that there are two varieties of sampling methods for cleaning validation: direct and oblique.

(a fictious organization) to guidance the Quality Control Protein lab by analyzing the concentration of our in-property requirements Utilized in conjugation with analytical tests.

Documents related to the merchandise you have acquired in the past happen to be gathered in the Document Library for your personal comfort.

Identify your collection: Name should be fewer than people Opt for a group: Not able to load your collection on account of an error

Pharmaguideline is actually a pharmaceutical site in which pharmaceutical principles are spelled out in very simple and easily understandable language for professionals and students. All posts and SOPs are created by Ankur Choudhary.

4. Any deviation or transform from this method ought to be documented and investigated. five. There have to be a published treatment or application for routine maintenance of equipment portion must be defined from the protocol.

The VMP also needs to determine the composition, roles and responsibilities, and the site’s normal validation system. 2nd, approaching validation and qualification utilizing Quality Risk Administration (QRM) principles is surely an expectation. This suggests identifying the scope and extent of validation or qualification for a selected task must be dependant on a threat evaluation. A chance evaluation that evaluates facilities, equipment, utilities, processes, and systems necessary to validation protocol analytical method the validation project and impact on present functions. Finishing risk assessments decide the extent of validation and notify validation protocols for just a project. What exactly is Qualification?

Validation also provides a framework to initiate entire control over the treatment, which displays efficiency, security and finally the method outcomes.

The quality of the product or service can't be adequately assured by in-process and completed-product or service inspection.

In-depth protocols for undertaking validations are essential in order that the process, whether solid dose, liquid or sterile, is sufficiently validated. Process validation protocols must contain:

The Functioning variety for just a method is described by the reduce and upper limitations of quantification (LLOQ and ULOQ, respectively). At least to the LLOQ, There exists multiple definition and these could be labeled as either identified based upon the alerts through the instrument or the calculated concentrations from samples.

Ongoing Process Monitoring: ongoing assurances that all processes keep on being in a state of control as a result of requalification/revalidation partial or total to accompany For illustration update or update.

Constantly Enabled Necessary cookies are Unquestionably essential for the web site to operate appropriately. here This group only includes cookies that guarantees standard functionalities and safety features of the web site. These cookies don't retail store any own information. Non-necessary Non-vital

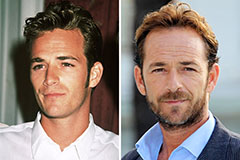

Luke Perry Then & Now!

Luke Perry Then & Now! Yasmine Bleeth Then & Now!

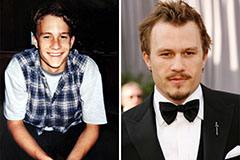

Yasmine Bleeth Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Nancy Kerrigan Then & Now!

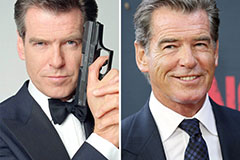

Nancy Kerrigan Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!